Skip to: main navigation | main content | sitemap | accessibility page

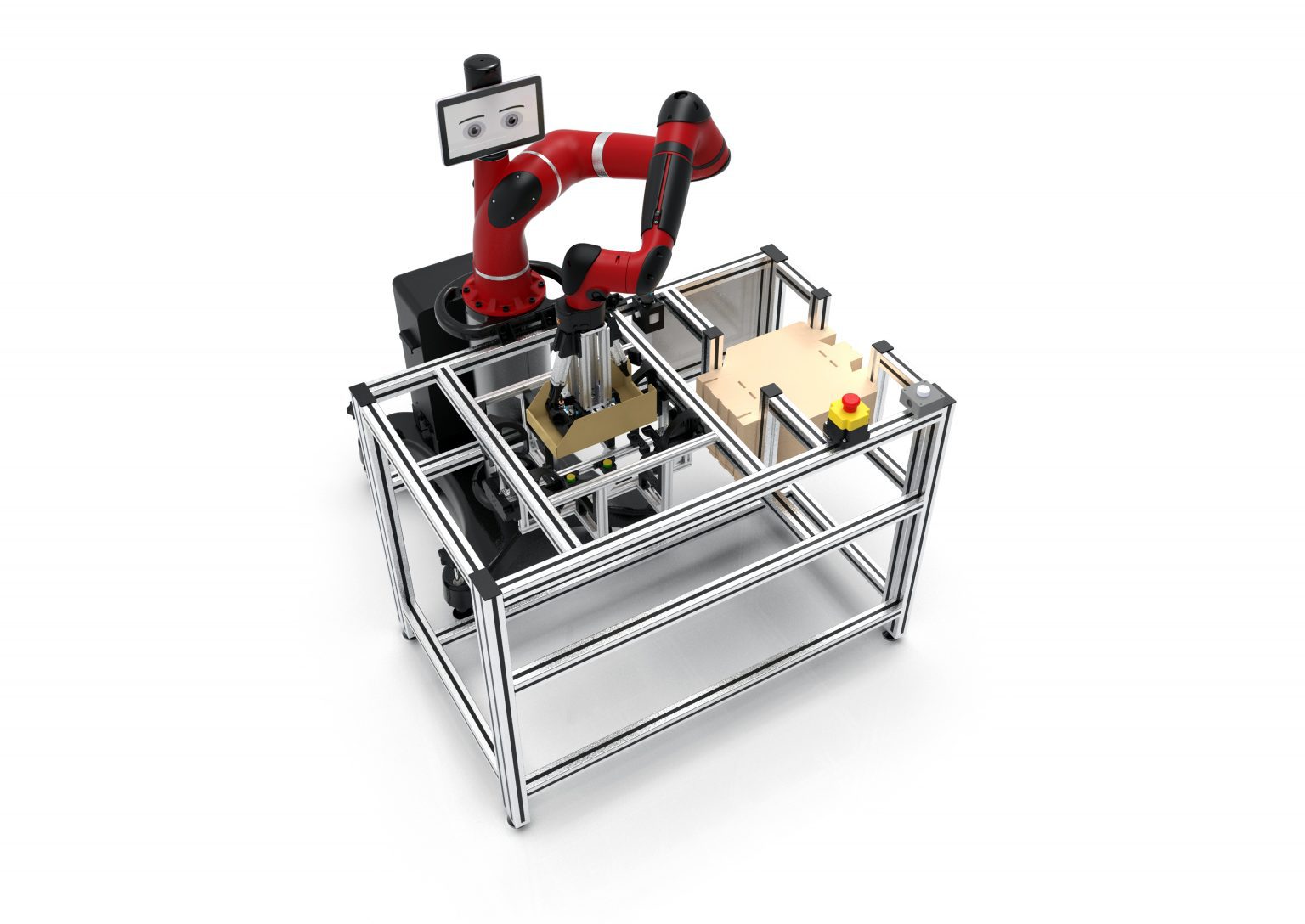

An agile automated unguarded collaborative robot cell designed to carry out the dull task of erecting cardboard trays typically used to hold and display pre-packaged foods and household goods on supermarket shelves. For example pizzas, cooked meat snacks, anti-bacterial wipes etc.

The Tray Erector is easily integrated with existing production lines and requires very little effort to move to different locations. It an operator-friendly human-machine interface (HMI). The dual tool feature comprises an inner forming tool and an outer forming tool with pneumatic actuators. The former is mounted onto a 4, 6 or 7 axis robot arm manipulator whilst the latter is fixed. They work in synch to erect the tray in its flat ‘net’ form by lifting the flaps and then folding and locking the tabs.

Dual tool

Easy setup

Handles multiple tray types and sizes

Small footprint at 1.5 sq.m

No programming skills required

Built-in safety features for operation around people

Operates on single phase power

Productivity rate

Infeed

Tray load (Max.)

Flat tray dimensions (w x l)(Max.)

Robot options

End effector

Interface

Compressed air

Power

Safety operation

5 cycles/min

Stack type. Depending on card thickness >200 units in flat form

1kg

600 x 600mm

KUKA iiwa

UR10e

Rethink Hahn Sawyer

Dual tool customised to tray shape and includes vacuum

HMI

Intera (Sawyer)

6 bar (min.) with 6mm pipe connection

Single phase 13A 230V AC

Force limited rams for unguarded operation (ISO/TS 15066: 2016 Robots and robotic devices — Collaborative robots

![]()

© 2003 - 2024 Active8 Robots (Active Robots Ltd.) All rights reserved.